Can We Scale Up Tree Propagation with Tissue Culture?

As a content and community manager, I leverage my expertise in plant biotechnology, passion for tissue culture, and writing skills to create compelling articles, simplifying intricate scientific concepts, and address your inquiries. As a dedicated science communicator, I strive to spark curiosity and foster a love for science in my audience.

Introduction

In forestry and agriculture, there is a consistent need for large volumes of high-quality, uniform planting material.

For decades, plant tissue culture, also known as micropropagation, has been explored as a method to meet this demand. It offers the potential to produce large numbers of genetically identical, disease-free plants from a single parent.

This process involves growing plant cells, tissues, or organs in a sterile, nutrient-rich laboratory environment. While effective for many high-value horticultural species, its application to large-scale forestry, particularly for mature woody trees, has faced significant biological and economic challenges.

Historically, these challenges—related to cost, labor, and biological limitations—have prevented micropropagation from becoming a widespread, cost-effective solution for mass tree production.

However, advancements in several key areas, including somatic embryogenesis, bioreactor design, automation, and gene editing, are systematically addressing these issues.

This article explains the foundational science of tree propagation with plant tissue culture, the barriers to its scaling, and the technologies being implemented to make it a more viable industrial process.

The Biological Foundations of Micropropagation

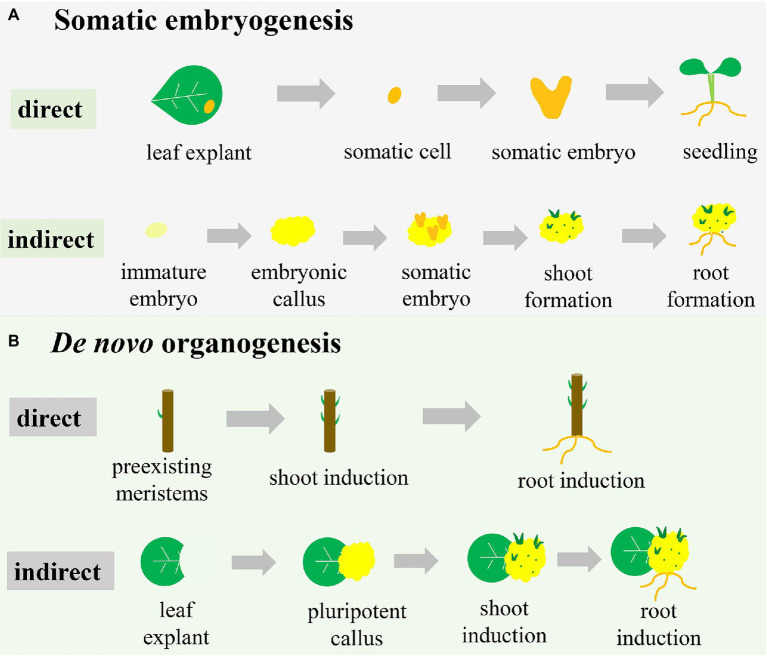

Plant tissue culture is possible due to a biological property called totipotency. This principle underpins tree propagation through tissue culture, enabling a single plant cell to regenerate into a complete, whole plant. In a laboratory, this capacity can be guided down two primary pathways:

-

Organogenesis: This is the most common method. A piece of tissue (an explant, such as a shoot tip or bud) is placed on a nutrient gel. Plant growth regulators (hormones) are used to induce the formation of organs. First, cytokinins are used to stimulate the growth of multiple shoots (multiplication stage). Then, these individual shoots are separated and moved to a different medium with auxins to induce root formation.

-

Somatic Embryogenesis (SE): In this pathway, somatic (non-reproductive) cells are induced to form embryos, which are structurally similar to the zygotic embryos found in seeds. These somatic embryos develop into complete plantlets that possess both a shoot and a root system from the beginning.

Figure: Different pathways of plant regeneration.

Source: Long, Y., Yang, Y., Pan, G., & Shen, Y. (2022). New Insights Into Tissue Culture Plant-Regeneration Mechanisms.Frontiers in plant science,13, 926752. https://doi.org/10.3389/fpls.2022.926752

The Standard Four-Stage Process (Organogenesis)

The traditional micropropagation workflow is divided into four distinct stages:

-

Stage 1: Establishment. The explant is sterilized and placed on a sterile nutrient medium.

-

Stage 2: Multiplication. The established culture is transferred to a medium that encourages it to produce multiple new shoots. This step is repeated multiple times (subculturing) to increase the number of shoots.

-

Stage 3: Rooting. The individual shoots are separated and placed on a medium designed to promote root growth.

-

Stage 4: Acclimatization. The small plantlets, which have been growing in a high-humidity, sterile environment with provided sugars, are transferred to soil. They must be "hardened" in a greenhouse, a process that gradually adapts them to lower humidity, non-sterile conditions, and the need to perform their own photosynthesis.

While functional, this multi-stage process presents several bottlenecks that make scaling difficult and expensive.

Barriers to Scaling Traditional Micropropagation

Efforts to scale the four-stage process for mass production, especially for woody trees, encounter significant, interconnected challenges.

Biological Barriers

-

Recalcitrance: Many plant species, especially mature trees like conifers, are "recalcitrant," meaning their tissues do not respond well to in vitro culture conditions. They fail to grow, multiply, or regenerate.

-

Phenolic Browning: When cut, many woody plant tissues release phenolic compounds. These compounds oxidize, turning the nutrient medium brown and releasing substances that are toxic to the plant tissue, inhibiting its growth or killing it.

Operational Barriers

-

Contamination: The nutrient-rich, high-sugar media are also ideal for the growth of bacteria, fungi, and yeast. Maintaining a completely sterile (aseptic) environment is critical, and any contamination can lead to the loss of entire culture batches.

-

Acclimatization Failure: Stage 4 is a common point of failure. The plantlets are physiologically delicate and adapted to the lab environment. The transition to a greenhouse causes significant stress, often resulting in high mortality rates.

-

Somaclonal Variation: The in vitro environment and the high levels of growth regulators used can induce genetic or epigenetic changes in the cells over time. This "somaclonal variation" results in plants that are no longer true genetic copies of the parent, which defeats the purpose of clonal propagation.

Economic Barriers

-

High Capital Investment: A tissue culture lab requires expensive, specialized equipment, including laminar flow hoods for sterile work, autoclaves for sterilization, and precisely controlled growth rooms.

-

High Operating Costs (Labor): This is the primary economic barrier. The standard four-stage method is "time- and labor-consuming." Labor costs frequently account for 50-70% of the total production cost. This is almost entirely due to the repetitive, manual subculturing required every few weeks to move tissues to fresh media during the multiplication stage.

These factors demonstrate that the biological problem of recalcitrance often leads to the economic problem of high labor costs, as difficult-to-grow tissues require more frequent and specialized manual interventions.

Technologies for Industrial Scale-Up

A different industrial model is required to overcome these barriers. This involves integrating several technologies that address the core issues of manual labor, biological limits, and process efficiency.

Process Innovation: Somatic Embryogenesis (SE)

For true mass production, somatic embryogenesis (SE) is often preferred over organogenesis. This is because embryogenic cells can be multiplied in a liquid medium, a process that is much more scalable than manually cutting shoots on solid gel.

A large volume of liquid culture can produce thousands of somatic embryos, each with the potential to become a whole plant. This method is better suited for automation and large-scale bioreactor production.

Hardware Innovation: Temporary Immersion Systems (TIS)

Propagating plants in a liquid culture solves the manual subculturing problem, but continuously submerging the tissues can lead to oxygen deprivation and poor development.

The solution is the Temporary Immersion Bioreactor (TIS). These are automated culture vessels that temporarily flood the plant tissues with the liquid nutrient medium for a short, programmed period (e.g., 10 minutes every 4 hours) and then drain it, leaving the tissues exposed to the air. This process provides nutrients while ensuring adequate gas exchange, leading to healthier, more robust plantlet development and higher multiplication rates.

Operational Innovation: Automation, Robotics, and AI

This layer of technology directly addresses the high labor costs and contamination risks.

-

Robotics: Automated systems using machine vision are being developed to perform the repetitive tasks of cutting, sorting, and transferring tissues. This reduces the need for manual handling, which in turn lowers both labor costs and the risk of contamination.

-

Artificial Intelligence (AI): Tissue culture protocols are highly complex: they involve many interacting variables (media components, hormone concentrations, light, temperature). AI and machine learning models can analyze large datasets from experiments to identify optimal protocols much faster than traditional trial-and-error, saving time and R&D costs.

Biological Engineering: CRISPR-Cas9

Gene editing tools like CRISPR-Cas9 offer a way to solve the most fundamental biological barriers.

-

Improving Tree Traits: CRISPR can be used to modify the tree's own genes. For example, it has been used in poplar to reduce lignin content, which lowers the cost and environmental impact of pulp and paper manufacturing.

-

Overcoming Recalcitrance: Researchers are using CRISPR to target the specific "developmental regulator" genes within the plant's DNA that control regeneration. By activating these genes, it may be possible to force recalcitrant tissues to regenerate, unlocking the most valuable and difficult-to-grow species for tissue culture.

Current Applications of Scaled Propagation

The scaling of tree propagation with tissue culture is already established in several key markets where the economics are favorable.

High-Success Forestry: Eucalyptus, Poplar, and Teak

For several industrial forestry species, micropropagation is a mature technology.

-

Eucalyptus (Pulp/Hardwood): Tissue culture is used to propagate high-yield F1 hybrids that cannot be reliably grown from seed.

-

Populus (Poplar - Pulp/Bioenergy): As a "model" species for tree biotechnology, poplar is easily cultured and is often the subject of advanced research, such as the low-lignin project.

-

Tectona (Teak - High-Value Timber): The high value of elite teak trees justifies the cost of tissue culture to clone superior individuals.

High-Success Horticulture: The Fruit Tree Rootstock Industry

In horticulture, tissue culture is often a necessary technology.

-

Citrus (Rootstocks): In response to diseases like Huanglongbing (HLB), new tolerant rootstocks have been developed. Since many of these do not propagate well by seed, tissue culture is the primary method used to supply them to growers.

-

Apple and Avocado (Rootstocks): Similarly, tissue culture is used to propagate apple rootstocks that are difficult to root conventionally and to meet the high demand for specific, clonally-propagated avocado rootstocks.

The Conifer Challenge: The Next R&D Frontier

The most valuable timber trees in the northern hemisphere, such as pines, firs, and spruce, are also the most recalcitrant. Industrial-scale somatic embryogenesis is the only feasible path for these species, but it remains a complex R&D challenge. Significant progress is being made in identifying the specific genes that control regeneration, which may soon unlock these species for mass production, marking the next frontier in tree propagation through tissue culture.

Global Economic and Policy Drivers

Beyond the value of a single species, large-scale demand is created by global trends:

-

Afforestation and Restoration Goals: National and international commitments to combat climate change (like the Bonn Challenge) and desertification require planting billions of trees. These large-scale projects create a massive, stable demand that can only be met with industrial-scale propagation.

-

Carbon Credit Markets: As companies and countries invest in "nature-based solutions" to offset emissions, forestry projects that can guarantee fast-growing, high-biomass trees become highly valuable. Tissue culture provides the uniform, elite clones needed for these predictable carbon-capture projects.

-

Disease Response: When a new disease threatens a key forestry species (like Ash Dieback in Europe), tissue culture can be used to rapidly screen for and propagate the few naturally resistant individuals, providing a long-term solution.

Final Assessment: The Path to Scaled Production

The question of whether tree propagation can be scaled with tissue culture is best answered with a "yes, depending on the species and the technology." The "vicious cycle" of the traditional, manual method has been addressed by a new set of tools.

-

For many horticultural species and some industrial trees (Eucalyptus, poplar), TC is already a mature, commercially viable technology.

-

For recalcitrant species like conifers, somatic embryogenesis and gene editing represent the most promising path forward, though significant R&D is still required.

The future of scaled tree propagation involves the increasing integration of somatic embryogenesis, TIS bioreactors, and robotic automation to reduce costs. In the longer term, advancements in gene editing to directly overcome recalcitrance will likely make in vitro propagation feasible for a much wider range of valuable tree species.

Equip Your Lab with Plant Cell Technology

The advanced processes described in this article—from establishing sterile cultures to scaling in bioreactors—require reliable, high-quality supplies. At Plant Cell Technology (PCT), we provide the essential products and expertise for modern plant propagation labs.

Our mission is to support researchers, commercial growers, and hobbyists by providing the tools needed to succeed.

Visit our website to explore our comprehensive catalog:

-

Contamination Control: Effectively manage contamination, a primary barrier to success, with our flagship product, PPM™ (Plant Preservative Mixture), a broad-spectrum biocide and fungicide.

-

Culture Media & Gelling Agents: Find a complete range of prepared media bases, including the industry-standard Murashige & Skoog (MS) medium, as well as high-clarity gelling agents like agar and gellan gum.

-

Plant Growth Regulators: We offer a full selection of high-purity auxins, cytokinins, and other hormones essential for directing organogenesis and embryogenesis.

-

Culture Vessels & Bioreactors: Scale your production with our selection of specialized culture vessels, from sterile jars and vented lids to advanced Temporary Immersion Systems (TIS) designed for efficient, high-volume propagation.

-

Educational Resources & Kits: Whether you are a professional or just starting, explore our extensive library of books, protocols, and starter kits to build your skills and troubleshoot challenges.

Move your project from the laboratory to industrial-scale production. Visit www.plantcelltechnology.com today to browse our full catalog, access technical protocols, and equip your lab for success.

Blog Categories

View by Level

Popular Blogs

The Technical Intersection of Tissue Culture and Genome Editing

Introduction The ability to modify a plant's genetic code has progressed at a remarkable rate. With the advent of CRISPR-based...

Read More

The Science of Better Multiplication and Rooting in Tissue Culture

Every tissue culture hobbyist or professional eventually hits a plateau. You have a protocol that works, you have your medium...

Read MoreSubscribe to Our Newsletter

Join the conversation

Your email address will not be published. Required fields are marked